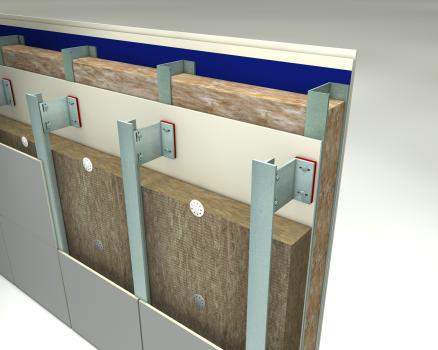

At Trade Insulations we stock many brands of fiberglass insulation. Fiberglass is commonly used in two types of insulation, slabs or blanket rolls with varying thermal properties. It is also available as rigid boards and can be used to insulate piping and for soundproofing too. Fiberglass insulation comes in slabs or rolls, can be blown-in, and can also be manufactured into boards.

Fiberglass insulation has been used in homes since the 1930s and was invented by Games Slayter, an engineer working for the Owens Corning Company. It has a long history and is still used in modern construction today, as well as being the most popular choice when looking at loft insulation.