Metal Framing Systems

Metal or steel framing systems are designed for the installation of walls and ceilings. The different types of metal frames have specific purposes when constructing a ceiling or wall.

Metal framing systems can be brought in the sizes and thicknesses required for your project needs and cut down to size if required. The choice of framing system can influence the efficiency and durability of the structure. Metal systems are well-used within the construction industry and stand out due to their exceptional strength and cost-effectiveness.

Here we will delve into the different types of metal systems, shedding light on three essential components, MF Ceilings, U track, and C Stud. These foundational elements not only offer additional structural integrity but also offer design possibilities.

MF Ceilings

MF (metal frame) Ceiling system, also referred to as a metal frame ceiling system, is a high-performing and durable suspended ceiling system that is designed for use alongside plasterboards. The components of MF systems include main runners, cross tees, and perimeter channels, on which plasterboards can be fixed onto.

MF Ceiling components are made up of the following:

MF6A – Perimeter Channel

The perimeter channel is the edge trim that is installed to provide a foundation for MF ceiling system. A wall trim that is fixed to the perimeter of the walls to support the ceiling system.

MF5 – Top Hat

The Top Hat – MF5 is the main section of the MF ceiling system and is connected to primary channel – MF7 underneath using metal furring clips – MF9. Plasterboard will be screwed to the MF5 systems to form the ceiling.

MF7 – Primary Channel

A Major structural component creating support for the furring sections which are connected to the primary channel using MF9.

MF9 – Metal Furring Clips

A preformed highly durable and secure wire clip for connecting the top hat – MF5 to the primary channel – MF7.

MF17 – Suspension Angle

Used to secure MF ceiling systems in place. The MF17 Suspension angle acts as a hanger for the MF ceiling frame to hang from. This product determines the depth or drop or the ceiling system and is ideal in applications where the ceiling height may vary.

MF Ceiling Vs U Track

MF Ceiling systems are composed of multiple metal products that are designed to create a ceiling system. The MF ceiling system is generally paired with plasterboard products to create the ceilings surface ready to decorate. The U track system is fixed to the ceiling and paired with plasterboard products and C studs to create the walls surface ready to decorate. Although the U track is applied to the ceiling, it is applied to create a wall frame, not the ceiling frame. The ceiling frame is made up of the MF ceiling system.

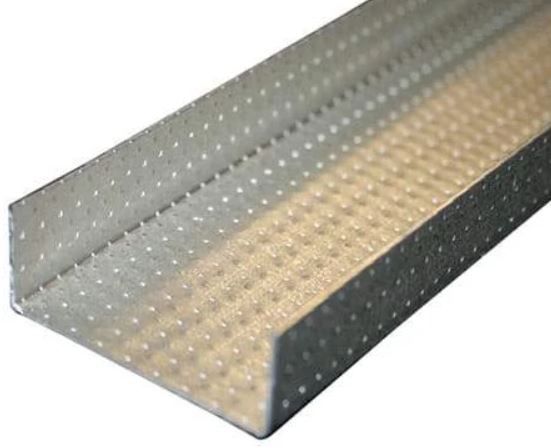

What are U Tracks?

U track is a high-quality metal framework used for horizontal support – the head and floor track in partitions and wall linings. U tracks are made from galvanised steel and are used to create wall partitions, suspended ceilings, framing systems, and other similar structures.

U tracks are also referred to as metal furring channels or metal stud tracks. U track metal provides structural support and alignment for plasterboard or drywall panels. The U shape frame holds friction fit insulation materials, plasterboard materials on each side and C stud framing systems within the track.

U tracks are available in thicknesses of 52mm and 72mm in lengths of 3000mm.

C Stud Vs U Track

The U track is designed for the horizontal support within wall framing systems – the top and bottom plates of the wall. C studs are designed for vertical support within wall framing systems – the studs fit inside of the horizontal metal furring channels on each side. Both the C stud and U track are required when constructing a framing system.

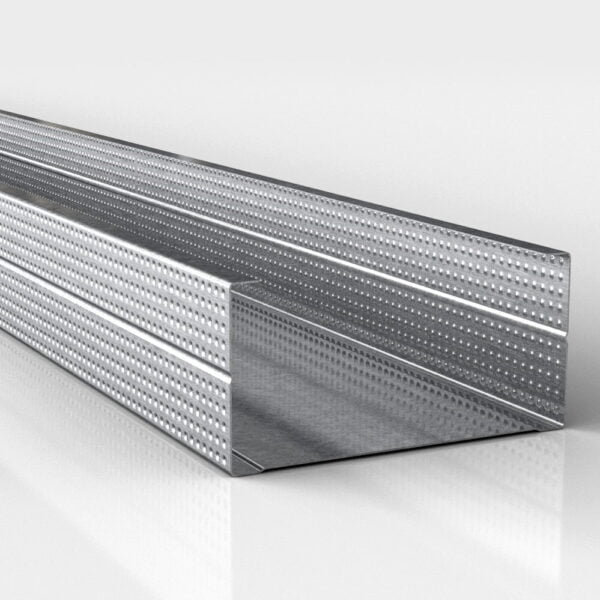

What are C Studs?

C studs are high-performance metal drylining stud wall components used for vertical support – the upright standing track in partitions and wall linings.

C studs are made from galvanised steel and are used within wall framing systems. The C shape is designed to friction fit insulation within the stud and to apply plasterboard to each side of the frame. The C stud also fits within the U tracks horizontal frame to form the walls edges.

C stud is compatible with any type of plasterboard, a selection of insulation materials, and U track systems. The studs are available in thicknesses from 50mm to 146mm and in lengths from 2400mm and 4200mm.

Metal Vs Timber

Should you use a frame timber or metal frame when building stud walls and partition walls? Well, this is a personal choice, and it comes down to what you know and preference. Here we have compared and measured up both timber and metal to help you make an informed decision.

The best place to buy timber

Check prices on treated timber now with our partner company Trade Timber

Below are comparisons between metal frames and timber frames.

Installation

Metal frames are significantly lighter than solid timber studs. This makes them easier to transport, store, and install.

Although Metal frames may be lighter in weight and easier to handle, timber frames can be quicker to assemble as less tools and labour is required to attach the elements together.

Costs

The cost of timber and metal can be dependent on a number of factors including the cut of timber, treated or untreated timber, and whether the materials are pre-constructed or built from scratch.

Metal materials are more cost-effective than timber. Whilst the metal materials are not always cheaper in price than timber materials, the long-term effectiveness and low maintenance results in long-term cost advantages.

Sustainability

Timber is thought to produce waste due to imperfections seen in some cuts of wood whereas steel frames are made to measure and do not produce as much waste. Timber is a natural product and does not require much energy usage to cut the wood size unlike metal framing systems. Both untreated clean wood and steel frame are recyclable.

Durability

Metal frames are highly durable and will not warp or rot overtime unlike a timber frames, it is also not vulnerable to the growth of mould. Metal and track framing systems are resistant to pests, ants, and termites, which have been known to destroy timber structures. It is important to note although metal is durable, it is not resistant to rust and corrosion.

Fire

The metal systems are fireproof and work well alongside other fireproofing materials such as fire-resistant insulation and plasterboards. Timber panels, joists, and rafters are most likely highly flammable and not fire resistant.

See a speed comparison of building a timber partition in comparison to metal.

Incorporating C studs, U tracks, and MF ceilings into construction and design projects including office spaces, residential properties, industrial facilities, and commercial buildings unlocks an incredible array of possibilities where strength and versatility is essential. These product offer sustainability, cost-effectiveness, durability and reliability.

Here below are some great plasterboard brands that work well when used alongside metal framing systems: