| Dimensions | 1200 × 600 mm |

|---|---|

| Brand |

Rockwool |

| Thickness |

50mm |

| Material Type |

Rock Mineral |

| Pieces Per Pack |

24 Packs |

| Sales Unit |

Pallet |

| Unit Coverage |

69.12m2 |

| Manufacturers Reference |

181197 |

| Thermal Conductivity |

0.034W/mK |

| Density |

100kg/m3 |

| Fire Rating |

A1 Non Combustible |

| Edge Type |

Square |

| Facing |

Stone Wool |

| Weight (kg/m2) |

5kg/m2 |

| Product Range |

Rockwool RW5 Slabs |

Please note this item is a Special Order – see terms and conditions

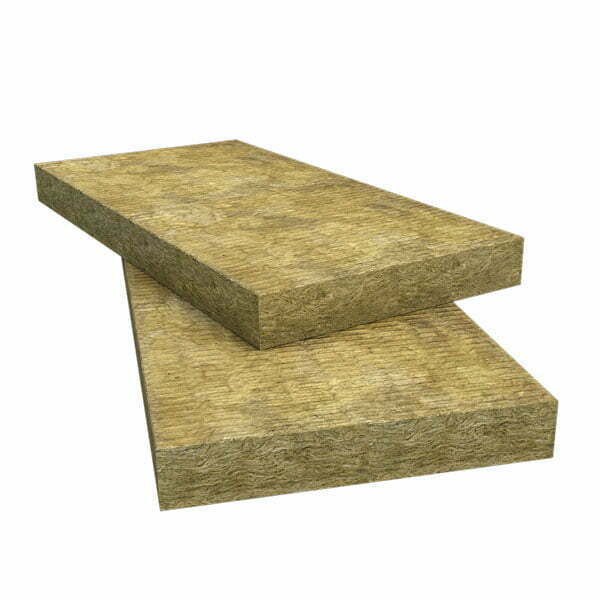

Rockwool RW5 50mm Acoustic Insulation Slab (1200 x 600mm) – 69.12m2 pallet

Request your delivery date in checkout

on orders over £350 +VAT

£798.00 Original price was: £798.00.£677.30Current price is: £677.30. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Quick deliveryTrustindex verifies that the original source of the review is Google. Excellent service, delivery and products. Very easy to place order online.Trustindex verifies that the original source of the review is Google. Delivery on the day requested, professional and helpful driver, good price, all products in good condition - would use again. Thanks!Trustindex verifies that the original source of the review is Google. All good, good price, turned up on time, all goods in perfect condition. Plus a friendly driverTrustindex verifies that the original source of the review is Google. Excellent company. I was able to arrange delivery date. Courteous delivery man . I would highly recommend to anyone.Trustindex verifies that the original source of the review is Google. Great company, much cheaper than my local builders merchant and delivered to my door in a couple of days. Very impressed 👍Trustindex verifies that the original source of the review is Google. Delivery guy went beyond and dropped the plasterboards off in the house instead of just leaving it on the kerb side. The plasterboards arrived without any damage. Thank you.Trustindex verifies that the original source of the review is Google. Product exactly as advertised, all items arived in good order - quick and friendly delivery - I can definitely recommend themTrustindex verifies that the original source of the review is Google. Top-notch service! Fast delivery, great price, good stock, and a great delivery driver – what more could you ask for? Highly satisfied customer here.

ROCKWOOL RW5 is a slab of extremely reliable acoustic insulation material which enhance the acoustic, fire-proof, and thermal performance of the building/ structure. RW5 is a versatile robust insulation solution that can be used for a range of general building projects as well as specialist specifications such as commercial, leisure, industrial and more. The RW range of insulation is made of high-quality resin bonded slabs which are available in a range of densities and thicknesses that are designed to be used in a wide range of applications including walls, floors, roofs and more. The RW range can be customised with mineral black tissue (60gsm), mineral white tissue (100gsm), and aluminium foil facings, made to order.

The RW5 is 600mm by 1200mm, available in many thicknesses with a thermal conductivity of 0.035W/mK and a density of 100kg/m3.

The advantages of Rockwool RW5 include:

- Excellent thermal, acoustic and fire insulation

- Water repellent and non-hygroscopic

- Resists high temperatures

- Easy to handle and install

- Cost effective

- No maintenance

- Durable/ Long lasting

The durability of this product gives you high-quality insulation that is long-lasting and will continue being effective for as long as the building/ structure is intact. These slabs are extremely lightweight and be can cut to any size required using a sharp knife which can make transportation and application of the product simple and easy.

Acoustic Performance: Rockwool products work in two ways to reduce noise which include either absorbing the sounds at surface or by impeding the transmission of sound through an element of the structure. The way Rockwool RW slabs are made, make them ideal for use as a sound absorber, with characteristically high coefficients over a wide frequency range. When thicker rockwool is used and paired with a sheet of plasterboard the noise control can be improved further. These noises include conversation, video equipment, mechanical rooms, and ventilation systems.

Fire Reducing: RW5 has fire reducing qualities and will not burn or smoke which provides extra protection and reduces damage and fire spreading within houses and buildings.

Water Repellent: Rockwool RW5 also has water repellent qualities that can prevent moisture building up which can be the cause of damp, condensation and rot that can damage the property’s structure and affect the performance of the insulation.

Thermal Performance: Rockwool is mineral wool that provides insulation to the building/ structure by reducing the air flow throughout the building/ structure. Its high thermal efficiency can help reduce energy bills for heating and cooling in residential and commercial buildings. This is due to the outstanding thermal resistance of the wool used in RW5.

Rockwool RW5 can be installed in a range of methods. These methods include:

- Walls – metal partitions

- Roofs

- Floors

- Partition panels

- Boiler rooms

Safety:

- Non-combustible A1 Euroclass Reaction to Fire classification

- Compliance: BS EN 13162:2012, ISO 14001

- MED classed ships- DTLR MCA approval

How are Rockwool RW slabs installed?

- Rockwool RW slabs can be installed in a range of methods from the floor to the roof and can be customised to meet your projects needs if required.

- Ensure you have confirmed that your chosen insulation material is suitable for your projects needs and meets building regulations.

- This is a guide only and a building professional or architect should be consulted before insulation is installed into a property to avoid problems that cost time and money.

- The most common method of installing RW slabs is within metal or timber frame walls.

- The slabs sizes are designed to fit within timer or steel frame applications.

- When installing insulation slabs into a frame wall the entire frame should be filled with no gaps.

- Cut offs of the insulation materials can be used to fill smaller gaps.

The slabs should be measured and cut to size, if necessary, to fit into the walls metal or timber frame spacings. Ensure your chosen thickness of the slab, matches the depth of the frame.

The slab should push back into the frame and if joint, they should be tightly butted together when installed to avoid thermal bridging and improve thermal performance. The slabs should sit flush with the frame with no projections.

If the frame is a new wall and not against an existing wall, ensure one side of the frame is fitted with plasterboards before installing the RW5 slabs so they can be pushed back against the board to make installing quicker and easier.

When the entire frame is filled, plasterboard is then measured, cut, and applied to the frame with the required fixings. The finishing materials such as beading, scrim tape, plaster, and paint and can then be applied to complete the wall.

| Dimensions | 1200 × 600 mm |

|---|---|

| Brand |

Rockwool |

| Thickness |

50mm |

| Material Type |

Rock Mineral |

| Pieces Per Pack |

24 Packs |

| Sales Unit |

Pallet |

| Unit Coverage |

69.12m2 |

| Manufacturers Reference |

181197 |

| Thermal Conductivity |

0.034W/mK |

| Density |

100kg/m3 |

| Fire Rating |

A1 Non Combustible |

| Edge Type |

Square |

| Facing |

Stone Wool |

| Weight (kg/m2) |

5kg/m2 |

| Product Range |

Rockwool RW5 Slabs |

| Dimensions | 1200 × 600 mm |

|---|---|

| Brand |

Rockwool |

| Thickness |

50mm |

| Material Type |

Rock Mineral |

| Pieces Per Pack |

24 Packs |

| Sales Unit |

Pallet |

| Unit Coverage |

69.12m2 |

| Manufacturers Reference |

181197 |

| Thermal Conductivity |

0.034W/mK |

| Density |

100kg/m3 |

| Fire Rating |

A1 Non Combustible |

| Edge Type |

Square |

| Facing |

Stone Wool |

| Weight (kg/m2) |

5kg/m2 |

| Product Range |

Rockwool RW5 Slabs |

Juma –

I would use this company again

David –

Great product and service received

Luke –

The product was delivered quickly without any delays or issues. Very pleased with the service!

Adewale –

Professional standard

Xavier –

Used this in a school refurbishment. Excellent at preventing noise travel.