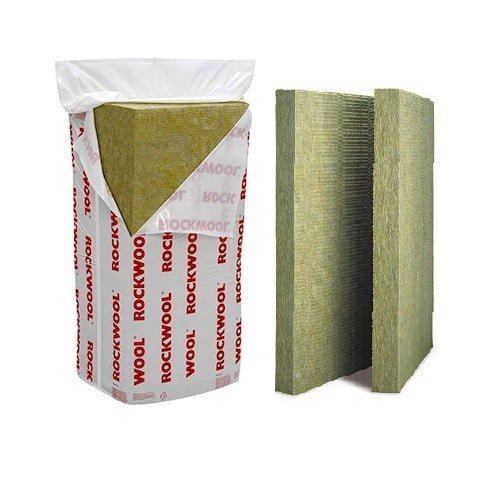

Rockwool RW3 Acoustic Insulation Slabs

ROCKWOOL RW3 is a slab of extremely reliable acoustic insulation material which enhance the acoustic, fire-proof, and thermal performance of the building/ structure. RW3 is a versatile robust insulation solution that can be used for a range of general building projects as well as specialist specifications such as commercial, leisure, industrial and more.

Showing all 8 results

Rockwool RW3 50mm Acoustic Insulation Slab (1200 x 600mm) – 5.76m2 pack

Original price was: £45.00.£37.50Current price is: £37.50.Rockwool RW3 100mm Acoustic Insulation Slab (1200 x 600mm) – 2.88m2 pack

Original price was: £41.63.£34.69Current price is: £34.69.Rockwool RW3 60mm Acoustic Insulation Slab (1200 x 600mm) – 51.84m2 pallet

Original price was: £497.66.£414.72Current price is: £414.72.Rockwool RW3 75mm Acoustic Insulation Slab (1200 x 600mm) – 4.32m2 pack

Original price was: £46.93.£39.11Current price is: £39.11.Rockwool RW3 90mm Acoustic Insulation Slab (1200 x 600mm) – 43.2m2 pallet

Original price was: £748.99.£624.16Current price is: £624.16.Rockwool RW3 30mm Acoustic Insulation Slab (1200 x 600mm) – 129.6m2 pallet

Original price was: £623.95.£519.96Current price is: £519.96.Rockwool RW3 40mm Acoustic Insulation Slab (1200 x 600mm) – 86.4m2 – pallet

Original price was: £560.18.£466.82Current price is: £466.82.Rockwool RW3 25mm Acoustic Insulation Slab (1200 x 600mm) – 103.68m2 pallet

Original price was: £622.70.£518.92Current price is: £518.92.The RW range of insulation is made of high-quality resin bonded slabs which are available in a range of densities and thicknesses that are designed to be used in a wide range of applications including walls, floors, roofs and more. The RW range can be customised with mineral black tissue (60gsm), mineral white tissue (100gsm), and aluminium foil facings, made to order.

The RW3 is 600mm by 1200mm, available in thicknesses from 25mm and 100mm. With a thermal conductivity of 0.034W/mK and a density of 60kg/m3.

The advantages of Rockwool RW3 include:

- Excellent thermal, acoustic and fire insulation

- Water repellent and non-hygroscopic

- Resists high temperatures

- Easy to handle and install

- Cost effective

- No maintenance

- Durable/ Long-lasting

The durability of this product gives you high-quality insulation that is long-lasting and will continue being effective for as long as the building/ structure is intact. These slabs are extremely lightweight and can be cut to any size required using a sharp knife which can make transportation and application of the product simple and easy.

How Are Rockwool RW3 Slabs Installed?

- Rockwool RW slabs can be installed in a range of methods from the floor to the roof and can be customised to meet your project's needs if required.

- Ensure you have confirmed that your chosen insulation material is suitable for your project's needs and meets building regulations.

- This is a guide only and a building professional or architect should be consulted before insulation is installed into a property to avoid problems that cost time and money.

- The most common method of installing RW slabs is within metal or timber frame walls.

- The slabs sizes are designed to fit within timer or steel frame applications.

- When installing insulation slabs into a frame wall the entire frame should be filled with no gaps.

- Cut offs of the insulation materials can be used to fill smaller gaps.

The slabs should be measured and cut to size, if necessary, to fit into the walls metal or timber frame spacings. Ensure your chosen thickness of the slab, matches the depth of the frame.

The slab should push back into the frame and if joint, they should be tightly butted together when installed to avoid thermal bridging and improve thermal performance. The slabs should sit flush with the frame with no projections.

If the frame is a new wall and not against an existing wall, ensure one side of the frame is fitted with plasterboards before installing the RW3 slabs so they can be pushed back against the board to make installing quicker and easier.

When the entire frame is filled, plasterboard is then measured, cut, and applied to the frame with the required fixings. The finishing materials such as beading, scrim tape, plaster, and paint and can then be applied to complete the wall.

Rockwool RW3 Density

The density of Rockwool RW3 is 60Kg per cubic meter. This is the same across the Rockwool RW3 range regardless of thickness.

Density in insulation refers to the amount of mass per unit volume of the insulation material. A denser insulation material would have more mass packed into the same amount of space compared to a less dense material. This density can affect the insulation's ability to resist heat flow, with denser materials usually providing better insulation because they contain more air pockets that trap heat. In general, higher density insulation tends to be more effective.

Rockwool MSDS

Rockwool RW Semi & Rigid Slab Installation Guide

Rockwool RW Slabs Datasheet