| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Knauf |

| Thickness |

12.5mm |

| Material Type |

Gypsum |

| Pieces Per Pack |

1 |

| Sales Unit |

Board |

| Unit Coverage |

2.88m2 |

| Thermal Conductivity |

0.19W/mK |

| Density |

648kg/m3 |

| Fire Rating |

Euroclass A2 |

| Facing |

Metallised Polyester Foil Laminate |

| Weight (kg/m2) |

8.3kg/m2 |

| Product Range |

Knauf Vapour Panel |

| Edge Type |

Tapered Edge |

This product only comes in tapered edge and not square edge

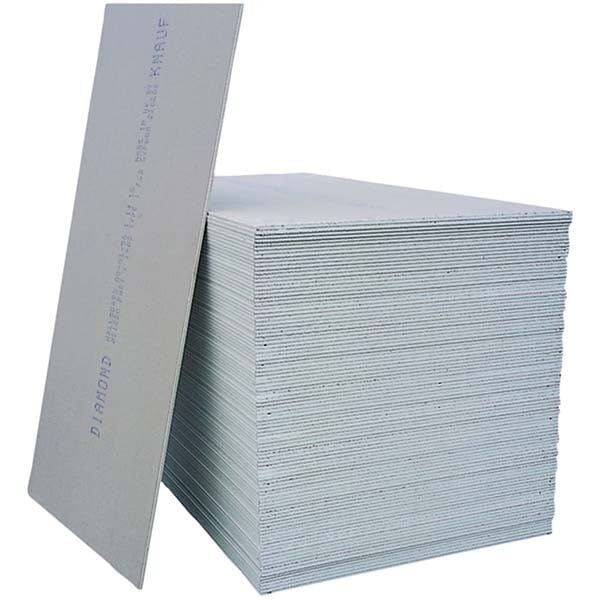

Knauf Plasterboard Vapour Panel 12.5mm (2400mm x 1200mm) (2.88m2) – Tapered Edge

Request your delivery date in checkout

on orders over £350 +VAT

£16.06 Original price was: £16.06.£14.04Current price is: £14.04. ex VAT

In Stock

This product only comes in tapered edge and not square edge

EXCELLENTTrustindex verifies that the original source of the review is Google. Superfast delivery and excellent communication, Would definitely recommend recommend.Trustindex verifies that the original source of the review is Google. My order was delivered promptly and correctly.James kept me informed re my delivery time and Karl checked in after to ensure all was ok . Will defo use againTrustindex verifies that the original source of the review is Google. best prices quick delivery 5* company will use again!!!Trustindex verifies that the original source of the review is Google. Very fast delivery, good products, I recommend 100% quality. The best price I have found. 👍👍👍Trustindex verifies that the original source of the review is Google. Great supplier very swift order and delivery. 5*will definitely use againTrustindex verifies that the original source of the review is Google. Purchased Rockwool for a dormer installation. Great price and delivered within a few days. Comunication throughout was excellent and recieved text on morning of delivery providing a time . Everything delivered ontime, as per order. First time user but will be using again. Would give 6 stars if I was able to. Thank you Fraya and trade insulations for a great experience.Trustindex verifies that the original source of the review is Google. Got some wall/roof insulation from them. Best deal I could find money wise and shipping was fast and everything arrived in good condition. Will definitely have a look at them for future purchases.Trustindex verifies that the original source of the review is Google. Speedy and efficient delivery, products exactly as expected.Trustindex verifies that the original source of the review is Google. Great insulation product and service, delivery was quick and efficient.Trustindex verifies that the original source of the review is Google. Excellent service, great communication. The item was delivered promptly with no issues. Highly recommended.

Knauf Vapour Panel is a drywall material made up of a high-quality gypsum core and quality paper linings on each side, designed to provide multi-purpose usage to provide a vapour barrier within your commercial or residential building. A must-have product with the building and construction industry. This simple product is easy to cut and install and can be applied to a variety of applications within a building and has a variety of different products available to suit different construction needs including partitions, linings & ceilings with standard performance requirements.

Knauf Vapour Panel has a metallised polyester foil laminated on the grey paper face, creating an effective vapour barrier

Key Features:

- Range of products available to suit any project

- Suitable for direct decoration or plaster finish

- Strong and adaptable

- Multi-purpose application

- A cost-effective choice

- Manufactured from high-quality gypsum

Knauf vapour panels can be cut by first measuring the space the panel is required for. Mark the relevant measurement onto the board and cut by using a sharp knife to score and snap or by using a fine-toothed saw. The board can be cut on a table or high surface to allow the saw to cut through the board.

Plasterboards are supplied on timber bearers. The packs should be lifted using a fork-lift truck and stacked not more than one-high on a flat surface to maintain good condition. Store the plasterboards in a clean and dry environment. Be cautious when moving not to knock the board’s edges and corners.

Simple and fast to install and can be paired with Knauf Metal Sections and accessories to provide a certified system. Knauf Performance Plus comes with an ivory paper face, making it easy to finish as well as to install. The boards can give 60 minutes of fire resistance from a single layer without the need for metal flat plates in horizontal joints and deflection heads.

The Knauf Drywall Plasterboard Range –

Knauf offers the right board for every application. Manufactured from the highest quality gypsum, Knauf plasterboards are versatile, strong, and easy to use. Special additives are used to provide a full variety of high-performance boards suited to acoustic, impact, fire-resisting, and moisture-resisting applications. Quick and simple to install and finish, the range covers all plasterboard needs. The range provides excellent performance that can achieve space division and separating walls, lift shaft protection and x-ray shielding.

Variables of impact, sound, fire, and moisture resistance extend the design possibilities, ensuring that all legislation and performance requirements can be met using the minimum number of components, cutting labour time and material cost.

The range uses 100% recycled paper liners from an FSC-certified paper mill. We use the most sustainable gypsum sources possible. Knauf Drywall plasterboard factories only use flue gas DE sulphurised (FGD) gypsum, a recycled material created as a by-product of controlling emissions from coal-fired power stations

Knauf vapour panel can be installed in a range of methods. These methods include:

- Below rafter level

- Ceiling applications

- Timber frame wall applications

- Steel frame wall applications

- Partition Wall applications

Safety Certifications:

Manufactured in accordance with ISO 14001

Manufactured to EN 520

In full compliance with ISO 9002 and BS1230: Part 1: 1985

More Information:

Brand: Knauf Vapour Panel

Length: 1800mm, 2400mm, 3000mm

Width: 900mm, 1200mm

Thickness: 12.5mm, 15mm

Material: Gypsum

Thermal Conductivity: 0.19W/mK

Datasheet:

| Thickness | Thermal Conductivity | Edge | Length | Width |

| (mm) | (W/mK) | T / S | (mm) | (mm) |

| 12.5 | 0.19 | Tapered Squared | 1800mm / 2400mm 3000mm | 900mm 1200mm |

| 15 | 0.19 | Tapered Squared | 1800mm / 2400mm 3000mm | 900mm 1200mm |

How are wallboards installed?

Plasterboards are generally fixed onto timber joists or rafters to create a neat wall finish before decorative step begin such as paint or plaster. The boards can be applied to the walls and ceiling and wooden rafter within loft spaces. The boards can also be used to secure other construction factors such as insulation materials. Other factors include fire proofing, sound proofing and so on, in which case the relevant board should be applied to the relevant area.

Wallboards can be installed by:

Depending on what method you are applying your board to, measure the relevant area.

Cut the boards to size if necessary, taking any opening such as windows and outlets into consideration. Wooden battens can be added to the area to help secure the boards depending on the area. The board can generally be fixed onto timber frames using the required screws and tools. Screws should be fixed at 10-20cm intervals and should not be too deep as the boards can crack. Position the board edge with the centre of the uprights. When joining boards ensure they are tightly butted together.

You should also stagger the boards so that, where possible, your seams don’t end up on the same stud. This will reduce the risk of cracks developing after you’ve applied your skim plaster finish.

When the boards have been fixed into place, they can either be decorated or if they need to be plastered, scrim tape should be applied to all board joins and corner beads to avoid the boards cracking or crumbling during the plastering process.

Before you begin:

- A building professional should always be consulted before starting any projects on your property to avoid damage and ensure building regulation are met. Construction mistakes can be extremely costly and time consuming.

- Ensure you have the correct building materials and equipment to complete the project.

| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Knauf |

| Thickness |

12.5mm |

| Material Type |

Gypsum |

| Pieces Per Pack |

1 |

| Sales Unit |

Board |

| Unit Coverage |

2.88m2 |

| Thermal Conductivity |

0.19W/mK |

| Density |

648kg/m3 |

| Fire Rating |

Euroclass A2 |

| Facing |

Metallised Polyester Foil Laminate |

| Weight (kg/m2) |

8.3kg/m2 |

| Product Range |

Knauf Vapour Panel |

| Edge Type |

Tapered Edge |

| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand |

Knauf |

| Thickness |

12.5mm |

| Material Type |

Gypsum |

| Pieces Per Pack |

1 |

| Sales Unit |

Board |

| Unit Coverage |

2.88m2 |

| Thermal Conductivity |

0.19W/mK |

| Density |

648kg/m3 |

| Fire Rating |

Euroclass A2 |

| Facing |

Metallised Polyester Foil Laminate |

| Weight (kg/m2) |

8.3kg/m2 |

| Product Range |

Knauf Vapour Panel |

| Edge Type |

Tapered Edge |

6 reviews for Knauf Plasterboard Vapour Panel 12.5mm (2400mm x 1200mm) (2.88m2) – Tapered Edge

Below are all of the datasheets for Knauf Plasterboards, please pick the relevant datasheet to your product below:

Knauf Standard Wallboard Plasterboard Datasheet

Knauf Fire Resistant Gypsum Board Datasheet

Knauf Moisture Panel Gypsum Board Datasheet

Jayden –

Really good quality & great for vapor control

Ed –

This product is fantastic quality for a reasonable price.

Nicholas –

0 issues

Lucas –

Easy to install with great results.

Zachary –

Not bad

Katie Jaggs –

Delivery was 20 minutes late but the price was good and they told me on the phone it would be late