| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

75mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

6 |

| Sales Unit |

Pack |

| Unit Coverage |

3.24m2 |

| Manufacturers Reference |

K10875 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

2.99kg/m2 |

| Product Range |

Kingspan K108 Cavity Board |

Please note this item is a Special Order – see terms and conditions

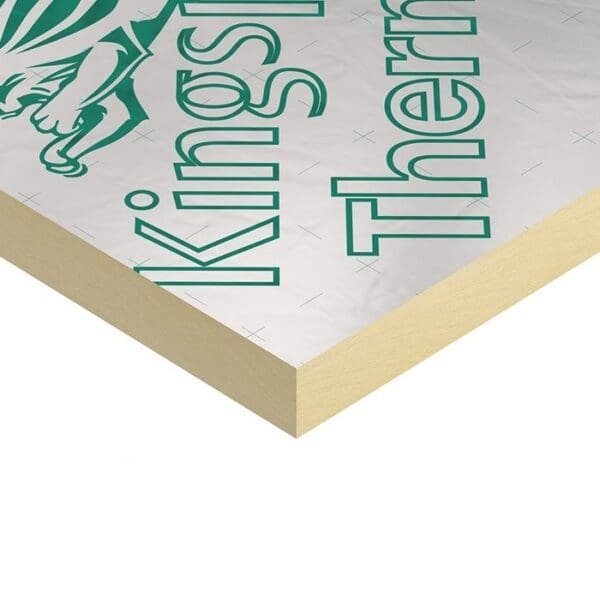

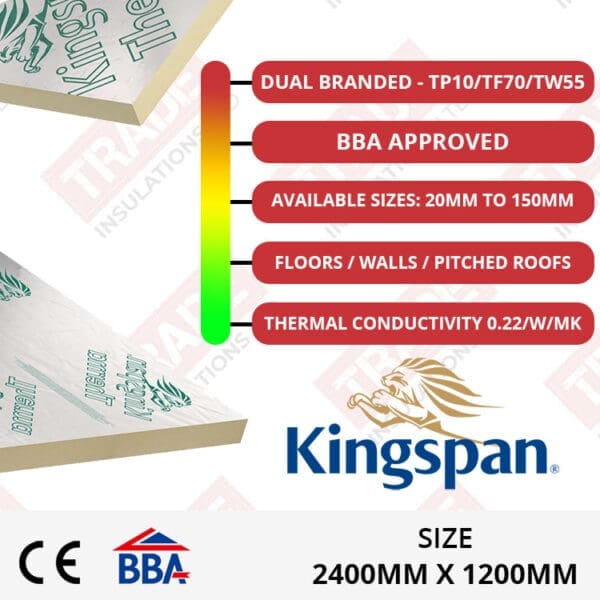

Kingspan K108 75mm Cavity Board Insulation (1200 x 450mm) – 3.24m2 pack

Request your delivery date in checkout

on orders over £350 +VAT

£119.00 Original price was: £119.00.£96.99Current price is: £96.99. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Great service, very easy to order and competitive prices.Trustindex verifies that the original source of the review is Google. A great company to deal with and highly reasponsive. A special mention to Freya, many thanks!Trustindex verifies that the original source of the review is Google. Great Prices, Delivery was spot on as statedTrustindex verifies that the original source of the review is Google. Great company to deal with. Web site was easy to use delivery was 3 working days. I would use them again.Trustindex verifies that the original source of the review is Google. Good quality product and fast delivery. Will be using them again.Trustindex verifies that the original source of the review is Google. Insulation delivered well and promptly. Everything i could’ve asked for, would use again and thoroughly recommended.Trustindex verifies that the original source of the review is Google. Good product good price and delivered on time pleasure to deal with thanksTrustindex verifies that the original source of the review is Google. Quality product, super quick delivery. Most of all the best price out there. Customer service was also brilliant too!

75mm K108

Kingspan K108 75mm is an insulation material manufactured with a phenolic core. The K108 Cavity wall insulation board has a thermoset fibre-free rigid phenolic core. Furthermore, the K108 board has a low emissivity composite foil facing on both sides.

Thermal – K108 has a thermal conductivity of just 0.019W/mK. The thermal conductivity means less heat will pass through the insulation boards. As a result, this will keep internal temperature level. The thermal properties of the K108 75mm will also prevent heat and energy escaping the walls of the building and because of this the building will be a much more comfortable space.

Sustainability – K108 cavity wall insulation will help by reducing the heat levels lost through the building. This will reduce the contribution to global warming and in conclusion, have positive effects on climate change. Moreover, the lack of heat loss can save money on energy bills up to 30%.

Resistance to solvents, fungi & rodents – The board is resistant to short-term contact with most dilute acids and other fluids. Clean spills off before the boards are installed. Do not use damaged boards with long contact to harsh solvents. K108 boards resist attack by mould and microbial growth. The board’s core does not provide food value to vermin.

Key Features of 75mm K108 Kingspan

- Lightweight as well as easy to cut, handle, and install

- Great thermal qualities

- Temperature controlled internal climate

- Saves money on monthly bills

- Long lasting lifespan

- Durable and reliable

- Full fill cavity insulation

- Resists moisture penetration

- Unaffected by air infiltration

- Non-deleterious material

- Free from harmful gases (CFC and HCFC)

- They do not add to the formation of any gases with Ozone Depletion Potential (ODP) or Global Warming Potential (GWP)

75mm K108 Cavity wall insulation is 1200mm x 450mm with thermal conductivity of 0.019W/mK.

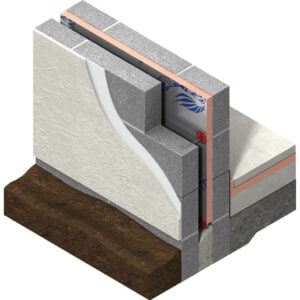

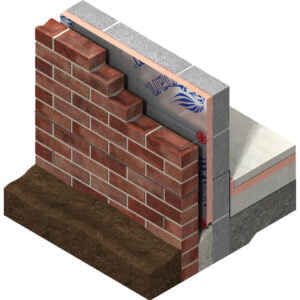

75mm Kingspan K108 Application

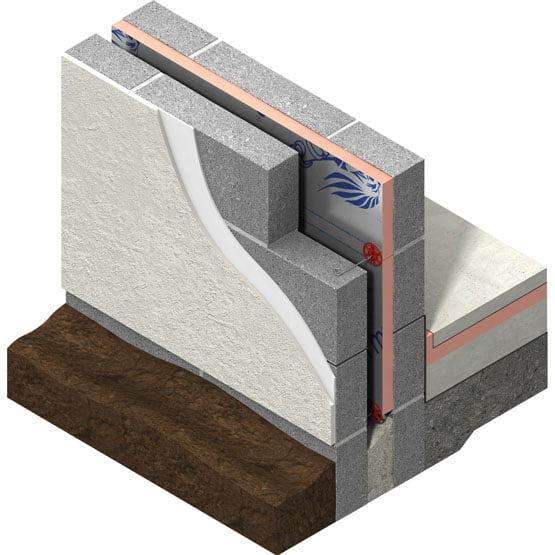

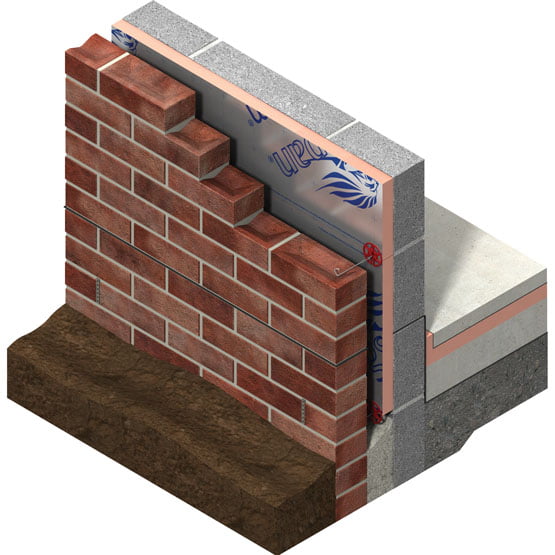

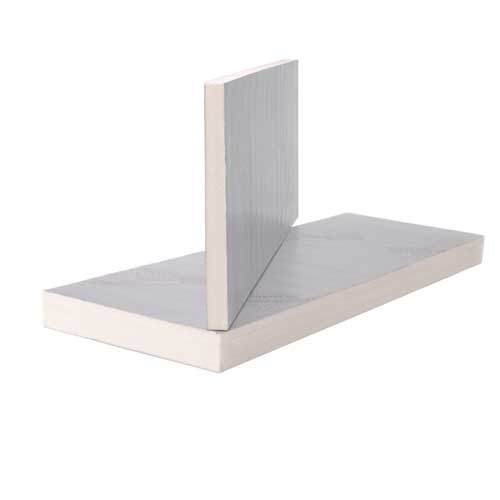

The K108 cavity wall boards are for partial fill masonry cavity wall insulation applications. K108 75mm boards are a rectangular shape. These boards are designed for easy installation fitted between wall ties.

The 75mm is a board designed for a specific application and most importantly, the K108 boards need to be installed whilst the walls are being built. The multi-purpose boards are designed for commercial, residential, and industrial buildings as well as new builds and refurbs. In addition, K108 can help to meet building regulations.

The boards are extremely durable and last lasting because the product performance will not reduce over time. In addition, the 75mm Cavity wall boards will last for as long as the building does. Therefore, the K108 75mm is a well-used product within the construction industry. Moreover, the thickness of the 75mm board means this board gives great quality thermal protection without taking up too much of the room.

Cut K108 cavity boards using a fine-toothed saw or a sharp knife. Use the sharp knife by scoring and snapping the boards and scoring the other side.

Always consult a building/construction professional before insulating your property because this can be a costly and time-effective mistake. Ensure the walls are free from condensation and mould before insulating. Please note, this is a guide only.

Note, the use of a cavity batten or cavity board is recommended to protect board edges and maintain a clear cavity.

How to Install K108 75mm Cavity Wall Boards

For a solid concrete ground floor, install the first row of wall ties is in the inner leaf at 600 mm horizontal centres a minimum of one course of blockwork below the damp proof course or 150 mm (for the UK) and 225 mm (for the Republic of Ireland) below the top surface of the ground floor perimeter insulation upstand, whichever is the lower.

Firstly, for a suspended timber floor, install the first row of wall ties in the inner leaf at 600 mm horizontal centres a minimum of 200 mm below the top surface of the ground floor perimeter insulation upstand.

After that, continue constructing the inner leaf up to the next wall tie course. (450 mm above the first). Position the next course of wall ties at the usual 900 mm horizontal centres in the UK and 750 mm horizontal centres in Ireland. Install the next course of blockwork to secure the ties.

Secondly, the first row of insulation boards should now be installed between the two rows of wall ties. Retain each insulation board tight against the inner leaf and lightly butt joints. Secure at a minimum of three points. After that, apply additional ties to satisfy the structural requirements or to ensure adequate retention of boards or cut pieces if needed.

Thirdly, build the outer leaf up to the level of the top of the boards and repeat the process. When insulating a gable, insulation boards should be continued 250 mm beyond the height of the top storey ceiling and a cavity tray installed above the insulation.

Furthermore, after raising each section of the inner leaf, before installation of the insulation board, excess mortar should be removed, and mortar droppings cleaned from exposed edges of the installed insulation boards.

75mm K108 Certifications

- ISO 9001: 2015 (Quality Management Systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- BS OHSAS 18001: 2007 (Occupational Health and Safety Management Systems. Requirements)

- BS EN ISO 50001: 2011 (Energy Management Systems. Requirements with guidance for use)

- The Harmonised Standard BS EN 13166: 2012 + A1: 2015 (Thermal insulation products for buildings. Factory made phenolic foam product).

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

75mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

6 |

| Sales Unit |

Pack |

| Unit Coverage |

3.24m2 |

| Manufacturers Reference |

K10875 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

2.99kg/m2 |

| Product Range |

Kingspan K108 Cavity Board |

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

75mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

6 |

| Sales Unit |

Pack |

| Unit Coverage |

3.24m2 |

| Manufacturers Reference |

K10875 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Composite Foil |

| Weight (kg/m2) |

2.99kg/m2 |

| Product Range |

Kingspan K108 Cavity Board |

9 reviews for Kingspan K108 75mm Cavity Board Insulation (1200 x 450mm) – 3.24m2 pack

Question: | What is the minimum gap for cavity wall insulation? |

maxfrommarble |

Answer: | 25mm-50mm. Partial fill solutions leave a 25mm-50mm gap between the cavity and external wall to reduce the chance of moisture tracking into the home | |

Question: | Do I need K106 or K108? |

maxfrommarble |

Answer: | K106 comes in two thicknesses, 90mm and 115mm for full fill applications whereas, K108 comes in thicknesses, 40mm – 150mm for partial fill applications. In short, the materials you need will depend on the required thickness and method of application. | |

Piotr –

No chasing, no delays, just straightforward, reliable delivery

Jack –

A real five-star experience!

Amina –

The ordering process is so simple

Nompumelelo –

Easy to handle and install. Noticed a big improvement in temperature control.

Quinn –

On par with Celotex, would sav your money

Igor –

Great.

Sandra –

Thank you very much for a straight forward ordering process.

Reuben –

Easy to order and delivery was spot on.

Stuart –

Put this in frame to insulate a wall that was causing a draught – brilliant