| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

90mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

4 |

| Sales Unit |

Pack |

| Unit Coverage |

2.16m2 |

| Manufacturers Reference |

K10690 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

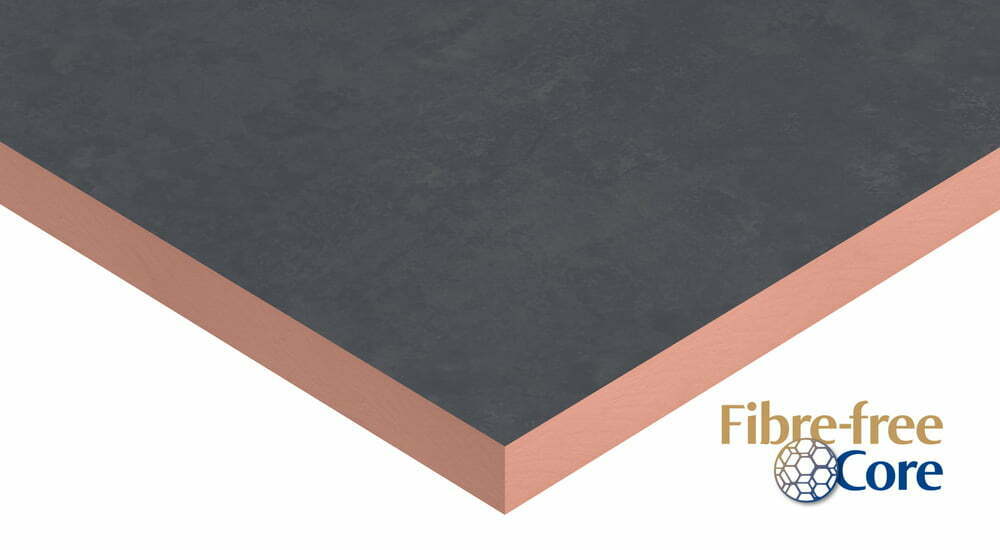

| Facing |

Polypropylene Fleece |

| Weight (kg/m2) |

3.36kg/m2 |

| Product Range |

Kingspan K106 Cavity Board |

Please note this item is a Special Order – see terms and conditions

Kingspan K106 90mm Cavity Board Insulation (1200 x 450mm) – 2.16m2 pack

Request your delivery date in checkout

on orders over £350 +VAT

£91.20 Original price was: £91.20.£77.15Current price is: £77.15. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Fast delivery all spot onTrustindex verifies that the original source of the review is Google. Karl was very helpful and very proffessional . i am a happy customer .Trustindex verifies that the original source of the review is Google. Insulation board delivered to schedule and in good condition.Trustindex verifies that the original source of the review is Google. Great price and fast deliveryTrustindex verifies that the original source of the review is Google. Good price.Fast and safe delivery. I will order again. 👍Trustindex verifies that the original source of the review is Google. We have used trade insulations various times now and they never disappoint. The team are always helpful and go above and beyond to make sure your order is delivered without any hiccups or stress. There website is easy to use and the process from finding the materials to having it delivered is seamless not to mention the prices on offer are incredibly competitive.Trustindex verifies that the original source of the review is Google. Great service, fast deliveryTrustindex verifies that the original source of the review is Google. First class service, great communication and priceTrustindex verifies that the original source of the review is Google. As always Great service, no problems with delivery, good product at fair prices⭐⭐⭐⭐⭐Trustindex verifies that the original source of the review is Google. Great products at a great price and delivered on the scheduled date. Great service! Great company!

90mm K106

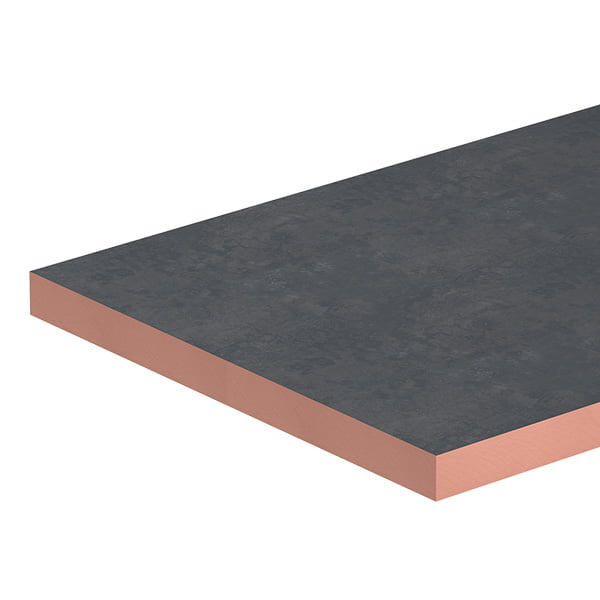

Kingspan K106 90mm is an insulation material manufactured with a phenolic core. The K106 Cavity wall insulation board has a thermoset fibre-free rigid phenolic core. The K106 board has a low emissivity composite foil facing on one side. In addition, the K106 board has a polypropylene fleece bonded the other side. As well as the 90mm board, the Kingspan K106 range offers a 115mm cavity wall board.

Sustainability – The K106 cavity wall board will help by reducing the heat levels lost through the building. This will reduce the contribution to global warming and in conclusion, have positive effects on climate change. Moreover, the lack of heat loss can save money on energy bills up to 30%.

Thermal – K106 has a thermal conductivity of just 0.019W/mK. The thermal conductivity means less heat will pass through the insulation boards. As a result, this will keel internal temperature level. The thermal properties of the K106 90mm will also prevent heat and energy escaping the building and because of this the building will be a much more comfortable space.

Storage – Stack the insulated plasterboards on a flat surface, within a cool and dry environment. If left outside, cover the boards with weatherproofing materials. Do not apply pressure to the boards. This includes walking on the boards to avoid damage. If applying excess weight to the boards, as a result they can crumble internally, and the thermal quality of the board will be affected.

90mm K106 (Full fill cavity insulation)

- Lightweight as well as easy to cut, handle, and install

- Great thermal qualities

- Temperature controlled internal climate

- Saves money on monthly bills

- Long lasting lifespan

- Durable and reliable

- Full fill cavity insulation

- Resists moisture penetration

- Unaffected by air infiltration

90mm K106 Cavity wall insulation is 1200mm x 450mm with a thermal conductivity of 0.019W/mK.

Kingspan K106 Applictions

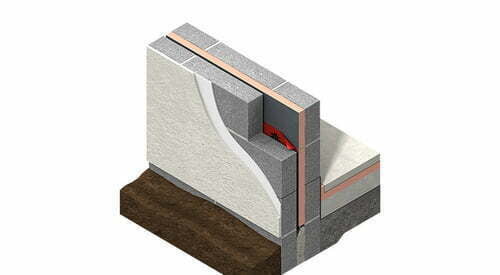

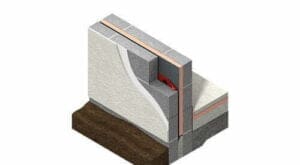

K106 90mm boards are rectangular in shape. These boards are designed for easy installation. The K106 are for full-fill cavity wall insulation applications.

The 90mm is a board designed for a specific application and most importantly, the K106 boards need to be installed whilst the walls are being built. The multi-purpose boards are designed for commercial, residential, and industrial buildings as well as new builds and refurbs. In addition, K106 can help to meet building regulations.

The boards are extremely durable and last lasting. In addition, the 90mm Cavity wall board will last for as long as the building does. The product performance will not reduce over time. Therefore, the Kingspan K106 90mm is a well-used product within the construction industry. Moreover, the thinner nature of the 90mm board means this board is great for improving thermal quality whilst keep as much space as possible.

How to Install K106 90mm Cavity Wall Boards

Cut K106 cavity boards using a fine-toothed saw or a sharp knife. Use the sharp knife by scoring and snapping the boards and scoring the other side.

Always consult a building / construction professional before insulation your property because this can be a costly and time effective mistake. Ensure the walls are free from condensation and mould before insulating. Please note this is a guide only.

Firstly, install wall ties in the inner leaf at 600mm horizontal centres.

For suspended timber floors, wall ties start a minimum of 150mm below the top surface of the ground floor perimeter insulation upstand or 200mm for suspended timber floors. Place the wall ties 900mm apart. Continue to construct the inner leaf up to the next wall tie course. (450mm above the previous inner leaf). After that, position the next course of wall ties at regular horizontal centres. Position extra wall ties at jambs for all openings. The next course of blockwork will secure the ties.

Remove excess mortar and mortar droppings as you go. Clean from exposed edges of the installed insulation boards.

Secondly, the first row of insulation boards should be installed between the two rows of wall ties (fleece must face outwards to cavity). Ensure each insulation board is retained tight against the inner leaf and most importantly, joints are butted.

After that, secure each board at a minimum of three points. Additional ties may also be required to satisfy structural requirements or to ensure adequate retention of the boards or cut pieces.

The next course of wall ties is positioned at the usual 900 mm horizontal centres. The next course of blockwork is installed to secure the ties.

Thirdly, apply a self-adhesive breathable tape to all horizontal and vertical joints, board edges and abutting junction interfaces.

These surfaces should be clean, dry and free from grease, dust, and dirt prior to application.

Fourthly, build the outer leaf to the level of the top of the boards. After that, repeat the process. (Cavity of 10mm or less). See the installation video here –

90mm K106 Certifications

- ISO 9001: 2015 (Quality Management Systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- BS OHSAS 18001: 2007 (Occupational Health and Safety Management Systems. Requirements)

- BS EN ISO 50001: 2011 (Energy Management Systems. Requirements with guidance for use)

- The Harmonised Standard BS EN 13166: 2012 + A1: 2015 (Thermal insulation products for buildings. Factory made phenolic foam (PF) products. Specification)

- BES 6001 (Responsible Sourcing – Good)

- ISO 37301: 2021

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

90mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

4 |

| Sales Unit |

Pack |

| Unit Coverage |

2.16m2 |

| Manufacturers Reference |

K10690 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Polypropylene Fleece |

| Weight (kg/m2) |

3.36kg/m2 |

| Product Range |

Kingspan K106 Cavity Board |

| Dimensions | 1200 × 450 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

90mm |

| Material Type |

Phenolic |

| Pieces Per Pack |

4 |

| Sales Unit |

Pack |

| Unit Coverage |

2.16m2 |

| Manufacturers Reference |

K10690 |

| Thermal Conductivity |

0.019W/mK |

| Density |

40kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Square |

| Facing |

Polypropylene Fleece |

| Weight (kg/m2) |

3.36kg/m2 |

| Product Range |

Kingspan K106 Cavity Board |

15 reviews for Kingspan K106 90mm Cavity Board Insulation (1200 x 450mm) – 2.16m2 pack

Question: | Can I use K106 in the floor? |

tradein |

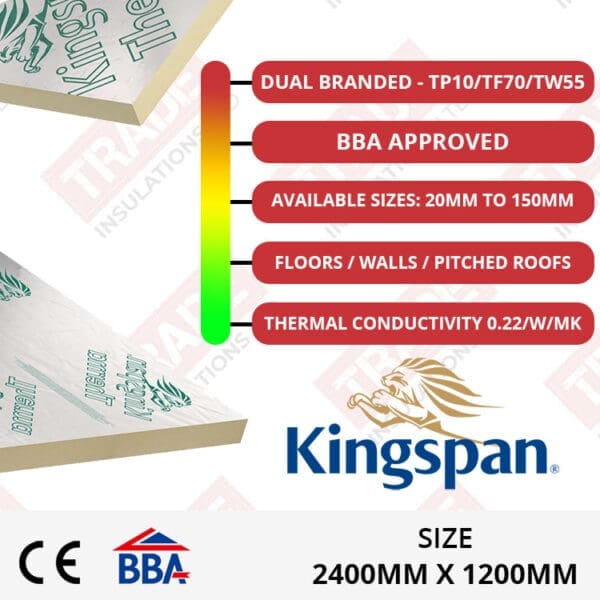

Answer: | the application of full fill cavity walls only. Kingspan TP10, TF70, TW55, and K118 are great product to insulate the rest of your property. | |

Question: | Is K108 the same as K106? |

tradein |

Answer: | No, because K108 and K106 boards have different specifications. Kooltherm K108 is a partial fill cavity wall insulation however K106 is a full fill cavity wall insulation. K108 has foil facings on both sides whereas K106 has foil facings on one side and polypropylene fleece on the other. K108 has thickness from 40mm to 150mm. K106 has a 90mm board, and a 115mm board. | |

John –

The prices were competitive, and the service was fantastic.

Charles –

Great product! It’s definitely helped reduce heating costs in my home, and it fits perfectly between the studs

Priya –

My insulation arrived on time and the delivery process was smooth and hassle-free.

Wandile –

Great product for DIYers. Easy to install with noticeable results.

Logan –

A must have for new build walls

Owen –

This 90mm cavity board has been a game changer. I can 100% feel the difference

Elena –

No problems, all good.

Marina –

Very smooth from checkout to delivery.

Kelly A –

It came quick but I ordered the wrong one. I realised that I needed the partial fill board not the full fill. What can I do to swap this?

Mark C –

Prompt delivery of K106 90mm Boards. Impressive customer service and appreciate the after call. Will return on the next job.

Mary Hillkinz –

price okay / delivery okay / all round was good, do you sell plasterboards? if so can I have a price on 42 sheets of siniat thank you.

Louis Wagtail –

Good all round product, had to order some more as thought the size of boards was 2400×1200 like the other Kingspan TP10 boards but these are 1200x450mm

Rachel Dreamer –

Phoned my local builders merchants who advised it is a 3 week lead time on Kingspan K106 then tried charging me double the cost. Phoned Trade Insulations and spoke to Steve in sales who booked it in for same week delivery. What can I say great service / fantastic price / will not be going to my local supplier after this!!

John Braknely –

Lovely price on K106 90mm and delivered in 3 days

Bob Wiggins –

Good prices