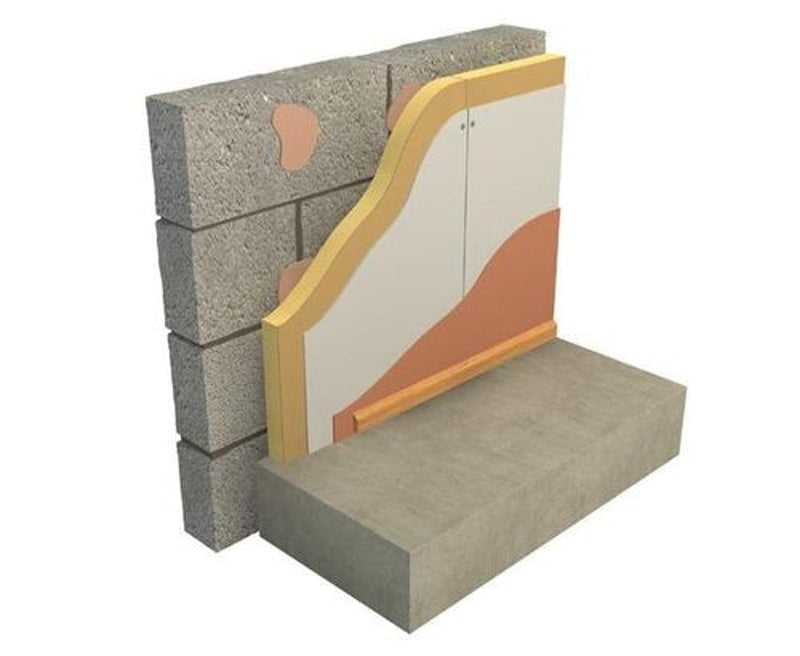

Ecotherm insulated plasterboards are designed to be installed within a property to improve thermal conductivity. Ecotherm insulated plasterboards are made up of a fibre-free rigid polyisocyanurate (PIR) core with a bilaminate foil / kraft paper facing bonded to one side. The other side of the insulations board is fixed to a 12.5mm plasterboard during the manufacturing process. The boards are manufactured with Zero Ozone Depletion Potential (ODP) and Zero Global Warming potential (GWP), free from CFC and HCFC.

The boards are available in sizes 1200mm by 2400mm with sizes ranging from 37.5mm to 72.5mm. This is made up of a (PIR) foam board and 12.5mm plasterboard, for example, a 25mm board attached to 12.5mm plasterboard will amount to a 37.5mm insulated plasterboard. This board provides a thermal conductivity of just 0.022W/mK. The boards are lightweight and easy to cut, handle, and install. A fine-toothed saw is recommended to cut insulated plasterboards. A plank of wood or ruler can be a handy tool to create a cutting guide and hold the board in place.

Key Features:

- Simple solution to upgrading walls and roofs.

- Enables thermal insulation and internal finish to be applied in one operation.

- Ideal for both new build and renovation projects

- Multi-purpose applications

- Green Guide Rating A+

- 120 kPa when tested at 10% compression

- Will not rot, sag or decay

- Quick and cost effective

- BBA Approved

Insulated plasterboards can be applied to the interior walls within a property. The two in one insulated plasterboard insulates and drylines walls in one method which can make the insulation process quicker as plasterboard will not need to be applied to the insulation boards after they are installed. Once the insulated plasterboards have been installed the next step of applying plaster can be applied.

Applications include both new build and upgrading the thermal performance of existing building elements, providing a cost-effective means of reducing CO2 emissions and for compliance with Building Regulations / Standards. This product can be applied with mechanically fixing or dot and dab adhesive dry lining applications. This can be applied to new or existing walls

Ecotherm Eco-liner Boards can be installed in a range of methods. These methods include:

- Pitched roofs and cold flat roofs

- Room in the roof/loft conversions

- Floors

- Solid walls, cavity walls, timber frame walls

- Dormer cheeks

- Ceilings

Safety / Product Specifications:

Length: 2400m

Width: 1200mm

Thicknesses: 37.5mm, 52.5mm, 62.5mm, 72.5mm

Thermal Conductivity: 0.022W/mK.

Facing: Low emissivity foil

Certifications:

- ISO 9001

- ISO 14001

- BS OHSAS 18001

- BS EN 520:2004+A1:2009

- BS EN 13950: 2005.

Datasheet:

| Thickness | Thermal Conductivity | R – Value | Length | Width | Coverage Per Sheet |

| (mm) | (W/mK) | (m2K/W) | (m) | (mm) | (m2) |

| 37.5mm | 0.022 | 1.2 | 2400 | 1200 | 2.88 |

| 52.5mm | 0.022 | 1.85 | 2400 | 1200 | 2.88 |

| 62.5mm | 0.022 | 2.3 | 2400 | 1200 | 2.88 |

| 72.5mm | 0.022 | 2.8 | 2400 | 1200 | 2.88 |

How to install Ecotherm eco-liner insulated plasterboard using mechanical fixings:

Notes:

Ensure walls are structurally sound and are clean dry and free from protrusions. Remove any fittings and strip any paint or wallpaper. Place dustsheets where needed. Work should be carried out in well ventilated condition and protective gear such as eye goggles, protective clothing, gloves, and face masks is recommended.

Step 1:

Measure the eco-liner requirements and cut the boards accordingly using a fine-toothed saw allowing 5mm off from the floor to ceiling height. Take care when handling eco-liner as wet or damaged boards should not be used. Before fitting ensure any gaps around the perimeter of the wall openings or penetrations are sealed with a flexible sealant.

Step 2:

Each wall to be fitted with eco-liner will need battening with treated timber or a proprietary metal wall lining system. Measure or mark the wall to indicate the batten positions. Include all wall edges, opening and services. Before fixing, remember to attach 100mm strips of DPC to the back of each timber batten.

Step 3:

Vertical battens should be placed at a maximum of 600mm centres. Horizontal battens at both top and bottom and around openings. To fix, drill through the timber into wall and secure in place using woodscrews and wall plugs or all in one hammer fittings. Timbers can be packed out to ensure a level surface. Fixings should penetrate a minimum of 45mm into the is existing masonry and should be no more than 600mm apart and 75mm in from the end of each batten

Step 4:

Place eco-liner into position ensuring all adjoining boards are tightly butted and meet the centre lines of each batten. All joints should be staggered or break bonded. Secure the boards to the timber battens using drywall screws at 300mm centres and 200mm centres around openings and external corners.

Fixings should penetrate at least 25mm into the timber or penetrate at least 10mm into metal studding. Fixings should be no less than 10mm in from the edge of the board. Screw heads should finish just below the surface level of the plasterboard and should not penetrate the masonry.

Step 5:

Seal floor and ceiling gaps with PU filler foam and then flexible sealant or equivalent. Apply the sealant around any further joints or breaks. Then either tape and joint boards or skim walls as appropriate.

Please note this is just a guide and professional advice should be given before carrying out any building works or insulation installation in your home.

| Dimensions | 2400 × 1200 mm |

|---|---|

| Brand | Ecotherm |

| Thickness | 72.5mm |

| Material Type | Polyisocyanurate (PIR) |

| Pieces Per Pack | 1 |

| Sales Unit | Board |

| Unit Coverage | 2.88m2 |

| Manufacturers Reference | 100000021529 |

| Thermal Conductivity | 0.022W/mK |

| Density | 185kg/m3 |

| Fire Rating | Euroclass 0 |

| Edge Type | Tapered |

| Facing | Paper |

| Weight (kg/m2) | 11.31kg/m2 |

| Product Range | Ecotherm Insulated Plasterboard |

Charlotte –

I installed the Ecotherm Ecoliner 72.5mm insulated plasterboard in my attic conversion, and it’s performing really well

Thulani –

The insulation arrived on time, and the delivery team was punctual and professional.

Xavier –

Nice and quick installation

Jaz Kaleed –

Always get good service from here.