| Dimensions | 1250 × 600 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

60mm |

| Material Type |

Extruded Polystyrene (XPS) |

| Pieces Per Pack |

7 |

| Sales Unit |

Pack |

| Unit Coverage |

5.25m2 |

| Manufacturers Reference |

GG50060 |

| Thermal Conductivity |

0.034W/mK |

| Density |

35kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Rebated |

| Facing |

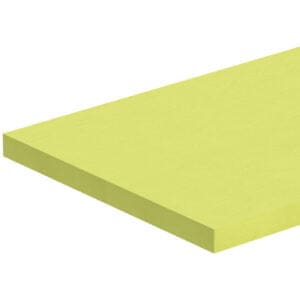

Green |

| Weight (kg/m2) |

2.1kg/m2 |

| Product Range |

Kingspan Greenguard |

Please note this item is a Special Order – see terms and conditions

60mm Kingspan Greenguard GG500 600mm x 1250mm – 5.25m2 pack – 60mm GG500

Request your delivery date in checkout

on orders over £350 +VAT

£80.50 Original price was: £80.50.£77.39Current price is: £77.39. ex VAT

In Stock

Please note this item is a Special Order – see terms and conditions

EXCELLENTTrustindex verifies that the original source of the review is Google. Ordered celotex pir boards of various sizes and rockwool rolls/slabs over 2 seperate deliveries for a loft conversion. Both times great communication via text, drivers friendly and great pricesTrustindex verifies that the original source of the review is Google. Speedy delivery and a very good priceTrustindex verifies that the original source of the review is Google. Good prices and delivered quickly, no hassle. Recommended.Trustindex verifies that the original source of the review is Google. V erry helpful company Delivery very prompt with helpful driverTrustindex verifies that the original source of the review is Google. Great service, thanks!Trustindex verifies that the original source of the review is Google. First time using Trade Insulations Ltd as a DIY'er - way cheaper than the household named stores with much better service! Great stuff.Trustindex verifies that the original source of the review is Google. Purchased Rockwool for a dormer installation. Great price and delivered within a few days. Comunication throughout was excellent and recieved text on morning of delivery providing a time . Everything delivered ontime, as per order. First time user but will be using again. Would give 6 stars if I was able to. Thank you Fraya and trade insulations for a great experience.Trustindex verifies that the original source of the review is Google. Great service, very easy to order and competitive prices.

60mm GG500

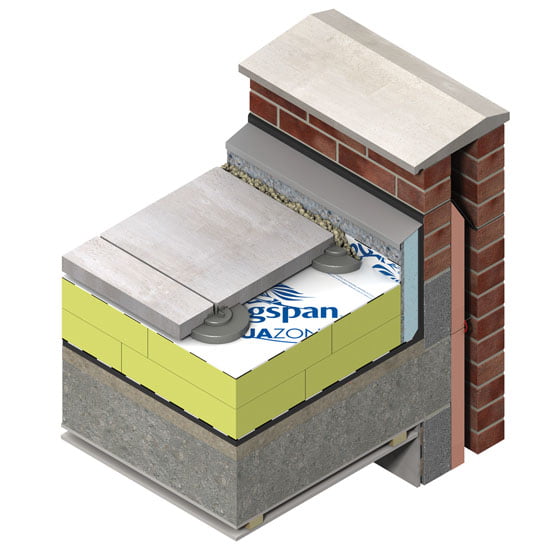

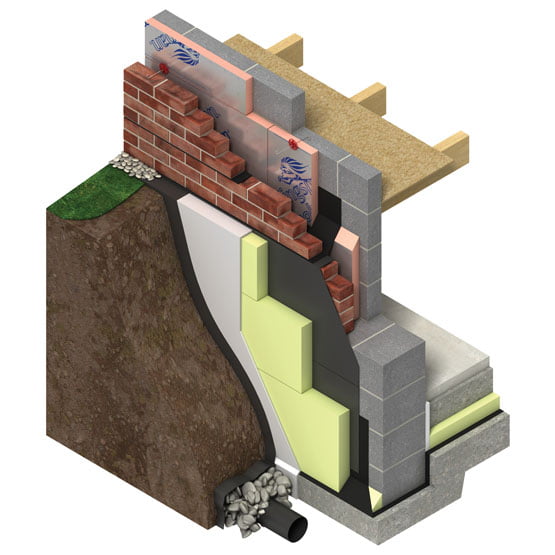

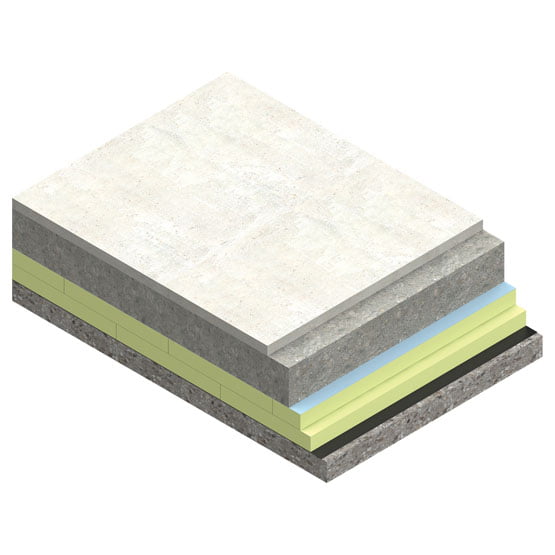

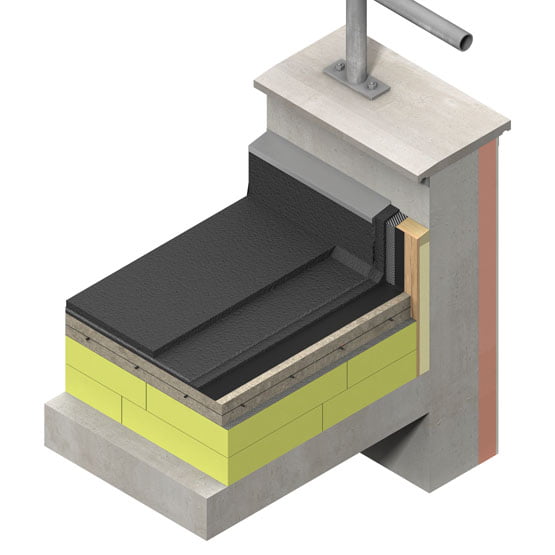

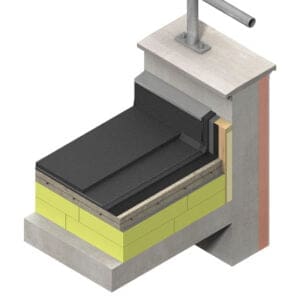

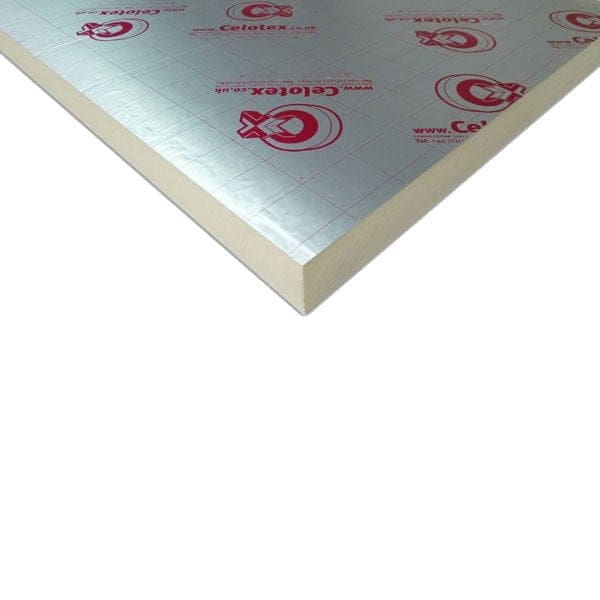

Kingspan GreenGuard GG500 is a high-performance rigid insulation board made up of extruded polystyrene designed for exterior insulation including the insulation of inverted roofs, basements, car park decks, and heavy-duty commercial, industrial, and cold store flooring. The GG500 boards have excellent compressive strength and a closed cell structure that is moisture resistant and rejects the absorption of groundwater and the passage of water vapour. The board is a chlorofluorocarbon (CFC), hydrochlorofluorocarbon (HCFC) free and manufactured with a blowing agent that has zero ozone depletion potential (ODP) and low global warming potential.

Key Features:

- High performance rigid extruded polystyrene insulation with low thermal conductivity.

- High compressive strength.

- Resistant to ground moisture penetration

- Easy to handle and install.

- Rebated Edges

- Compressive strength (minimum) at 10% compression – 300kPa

- Fibre-free rigid extruded polystyrene insulant

- Resistant to most dilute acids and alkalis

- Available for new builds or refurbishments

:

The Kingspan GreenGuard brand selection offers extruded polystyrene (XPS) insulation boards in a range of sizes, air barrier building wraps and accessories including flashing.

The XPS insulation board offers an R–value of 5.0 per inch of thickness and is the ideal product for a variety of applications including below slab, below grade along the foundation, inside basement walls, exterior insulation over wood sheathing and residing.

Rigid extruded polystyrene insulation (XPS) can also be used as general-purpose insulation for multiple applications including, roofing, wall and foundation applications requiring a minimum compressive strength.

Continuous insulation for above grade walls, as well as below grade walls and floors provides an extra barrier against moisture infiltration.

Each insulation product achieves the necessary fire performance for its intended application.

GreenGuard products are easily identifiable by their bright green colour. In addition to creating healthier, durable, and cost-efficient assemblies, GreenGuard products can help projects to meet environmental building certification requirements.

Cutting:

Kingspan Greenguard GG500 can be cut by measuring and marking to board to ensure an accurate fit and cutting with a fine-toothed saw on higher surface to allow the saw to cut through. Other ways to cut GG500 is to use a hot wire system or by scoring with a sharp knife and snapping the board over a edge and scoring the other side if necessary. Ensure accurate trimming to accomplish close-butting joints and continuity of insulation to avoid thermal bridging.

Packaging and Storage:

The polyethylene packaging of Kingspan Insulation products is fully recyclable and packaging materials should not be considered sufficient for outside protection. The boards should be stored on a flat surface inside a well-ventilated building. If, however, indoor storage is not an option, then the boards should be stacked clear of the ground and protected with a pale pigmented polythene sheet or weatherproof material. Kingspan GreenGuard should not be left exposed to the sun covered by either a transparent or a dark plastic sheet. In both cases the temperature of the board can build up and alter the board dimensions or warp them.

Please note Kingspan GreenGuard may be delivered in packaging showing alternative branding.

Kingspan Greenguard GG500 installation methods –

- Inverted roofs

- Basements

- Car park decks

- Heavy-duty commercial

- Industrial and cold store flooring

- Suitable for new builds and refurbishments

Please see below our Kingspan Greenguard GG500 Insulation Board datasheet and safety regulations.

Safety Certifications:

- ISO 9001: 2015 (Quality management systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- ISO 45001: 2018 (Health and Safety Management Systems. Requirements with guidance for use)

- ISO 50001: 2011 (Energy management systems. Requirements)

- Standard: BS EN 13164

- Fire performance: BS EN 13501-1: 2018, Euroclass RtF F

- Recycled content: 0% (minimum) to BS EN ISO 14021

More Information:

Length: 1250mm

Width: 600mm

Thicknesses: 50mm, 60mm, 80mm, 100mm

Thermal Conductivity: 0.034W/mK, 0.036W/mK

Material: Extruded Polystyrene

Colour: Green

Datasheet:

| Thickness | Thermal Conductivity | Length | Width | Sheets Per Pack | Coverage Per Pack |

| 50 | 0.034 | 1250 | 600 | 8 | 6 |

| 60 | 0.034 | 1250 | 600 | 7 | 5.25 |

| 80 | 0.036 | 1250 | 600 | 5 | 3.75 |

| 100 | 0.036 | 1250 | 600 | 4 | 3 |

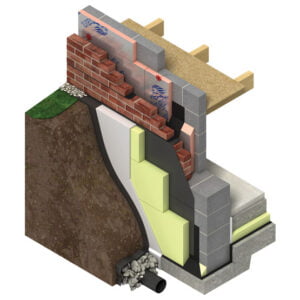

Installation Guide below a floor slab

Before the installation begins make sure that the site is prepared and foundations, where necessary, are built to damp proof course (DPC) level.

A thin sand blinding may be used to accomplish a continuous level surface that is free from projections over rolled hardcore.

The damp proof membrane (minimum 300 micron / 1200 gauge polythene) should be laid with joints well lapped and folded either directly over the well compacted hardcore prior to laying the insulation boards, or over the insulation boards. This will prevent the passage of ground water.

The membrane should be brought up the surrounding foundation walls until it is sufficiently above the height of the wall DPC so that it will connect with or form the damp proof course.

The insulation boards should always be loose-laid, break bonded, with joints lightly butting together.

If two or more layers of insulation materials are required, they should be horizontally offset relative to each other so that the two layers do not line up. The horizontal centre of the new board should line up with the join of the two butted boards below and should overlap the vertical joins of the board below.

To prevent thermal bridging. A strip of rigid insulation board (minimum 20 mm thick) should be placed vertically around the perimeter of the floor slab. The top of the strip of insulation board should be level with the top of the floor screed and the bottom should be level with the bottom of the horizontal floor insulation, and closely butted up to it.

If the DPM is laid directly onto the hardcore below the insulation boards, the boards should be overlaid with a polythene sheet (not less than 125 micron / 500 gauge), to prevent the wet concrete piercing through the joints between the boards, and to act as a vapour control layer. Ensure the polythene sheet has 150 mm overlaps and is taped at the joints and is turned up 100 mm at the walls.

The subsequent installation of the concrete slab and screed or other flooring material is carried out in a manner similar to that for an un-insulated floor. The concrete slab and screed should be allowed to dry out prior to the installation of the floor finish

| Dimensions | 1250 × 600 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

60mm |

| Material Type |

Extruded Polystyrene (XPS) |

| Pieces Per Pack |

7 |

| Sales Unit |

Pack |

| Unit Coverage |

5.25m2 |

| Manufacturers Reference |

GG50060 |

| Thermal Conductivity |

0.034W/mK |

| Density |

35kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Rebated |

| Facing |

Green |

| Weight (kg/m2) |

2.1kg/m2 |

| Product Range |

Kingspan Greenguard |

| Dimensions | 1250 × 600 mm |

|---|---|

| Brand |

Kingspan |

| Thickness |

60mm |

| Material Type |

Extruded Polystyrene (XPS) |

| Pieces Per Pack |

7 |

| Sales Unit |

Pack |

| Unit Coverage |

5.25m2 |

| Manufacturers Reference |

GG50060 |

| Thermal Conductivity |

0.034W/mK |

| Density |

35kg/m3 |

| Fire Rating |

Euroclass F |

| Edge Type |

Rebated |

| Facing |

Green |

| Weight (kg/m2) |

2.1kg/m2 |

| Product Range |

Kingspan Greenguard |

6 reviews for 60mm Kingspan Greenguard GG500 600mm x 1250mm – 5.25m2 pack – 60mm GG500

Kingspan Greenguard Basements Brochure

Kingspan Greenguard Car Parks Brochure

Kingspan Greenguard Inverted Roofs Brochure

Kingspan Greenguard Heavy Duty Brochure

Kingspan GG300 Declaration Of Performance

Kingspan GG500 Declaration Of Performance

Kingspan GG700 Declaration Of Performance

Kingspan Greenguard Safety Information

Patrick –

best prices i could find online

Francis –

Consistent quality and well-organized delivery service.

Sarah –

installed this insulation a few weeks ago. It’s performing as advertised

Mthobisi –

Easy to cut and install. Definitely a DIY-friendly insulation material.

Dhruv –

A staple in our construction projects. This insulation never fails to meet our expectations.”

Kevin –

5 Stars, all perfect.