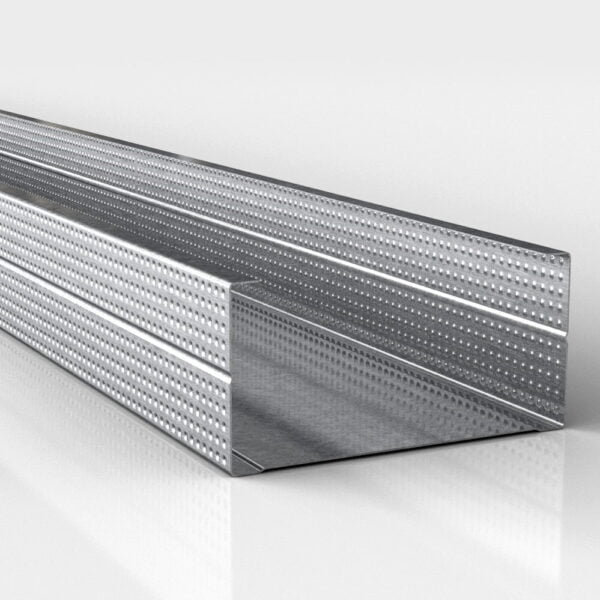

Metal C Stud

You can find a wide range of Metal C Studs at Trade Insulations. These are available in many different size options and are designed to aid the building of lightweight yet durable partition wall systems. C Metal Studs are often referred to as ‘C Studs’. C Studs provide the ideal structural framework for non-load-bearing walls. These are a vital part of metal partitioning stud systems and are typically made from lightweight galvanised steel. The primary benefit of C Stud Metal is that you can fix plasterboard directly to them. Galvanised steel also boasts both termite and fire-resistant properties. This makes it a great alternative to traditional timber framing systems. Order your Metal C Studs directly from us today.

C Metal Stud

Metal C Studs are a framing component vital in metal frame partitions and stud walls. Once built, you can effectively fix plasterboards or even specialist drywall. You can find lengths ranging from 2.4m to 4.2m on our website.

These types of metal studs are called 'C Studs' because when viewed cross-sectionally, it looks like a C's shape. When it comes to the manufacturing process, it begins by taking a coil of galvanised steel. The coil is then shaped into a 'C' using a cold rolling machine.

Brands such as Knauf or Siniat provide plasterboards, which form the overall drylining system when combined with metal framing systems. Metal C Studs are commonly used with U-tracks to create a secure and durable metal framework to support plasterboard. You can find metal framing systems in a wide variety of settings. These include commercial buildings such as offices, schools, hospitals and retail spaces where non-load-bearing partitions are required. Metal framing systems are also used in residential settings and industrial applications.

The Benefits Of Using Metal C Studs

Using Metal C Studs boasts many benefits when compared to traditional timber framing systems. These include:

- They offer fire resistance

- Metal C Studs are rot proof

- They are termite resistant

- C Stud Metal is made using galvanised steel

- They do not rust

- Metal Framing Systems are low maintainance

How to install C Studs in Metal Stud Partitions

Instaling Metal C Studs in a partitioning system is a straightforward process. Metal C Studs are lightweight and easy to handle and install. This makes them the perfect component for aiding the build of partitions.

There are two key stages in installing metal stud partitioning systems. The first stage is setting up the U Track framework, and the final stage is securing the plasterboard to the actual stud work.

Preparing and fixing the C Stud Framework

Metal C Studs need to be installed in unison with Metal U Tracks. U Tracks are vital as they act as a guiding channel for the vertical studs. They also ensure that they are aligned correctly. Metal U Tracks must be placed on the ceiling and floor. Ensure the U Track is 2mm wider than the C Stud for a secure fit. For example, if you are fitting a 70mm C Stud, ensure you purchase a 72mm U Track. You can buy everything you need on our website.

Once you have positioned your U Track, you must determine the spacing between the C Studs. A common practice is to install the C Studs at 600mm centres. Some builders may opt for 400mm spacing for additional strength or to meet the project scope. When you have determined the spacing, you can mark this out. C studs are easy to install into U Tracks as they can securely slow in using a wafer head self-drilling screw. The screws provide added strength and a strong base for drywall installation.

Building a metal framing system is a cost-effective solution and an alternative to timber framing systems. You can read more about metal framing systems in our helpful article. We always suggest you consult a building professional or architect for construction projects.

Fixing plasterboard to metal stud framework

Once the C Studs are securely slotted, the next step involves fixing the plasterboard. On our website, you can find a wide variety of plasterboard. Wallboard thickness is typically either 12.5mm or 15mm. The thickness you use will be dependent on your project requirements.

Position the plasterboard flush against the C studs for a nice, even fit. The board can then be fixed into the stud work using drywall screws. Fine thread drywall screws can be screwed into both the studs and the U track to ensure the board stays firmly in place.

C Channel Metal Studs

C channel Metal Studs, or, simply put, Metal C Studs, can be purchased in minutes via our website. We are proud to offer trade prices on our Metal C Stud range. At Trade Insulations, you don't need to be in the trade to qualify for trade prices.

If you want plasterboards, we also offer a vast selection from top brands such as Knauf, British Gypsum and Siniat.

Place your order today and discover why so many people use Trade Insulations to supply their C Studs, plasterboards and insulation.