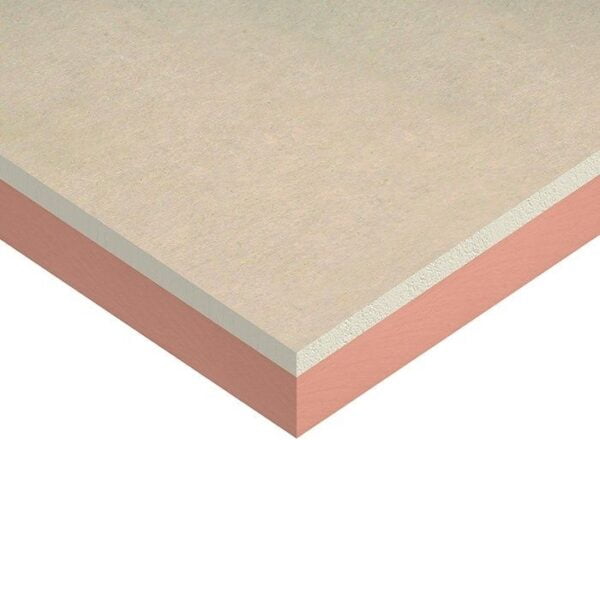

Kingspan K118 Insulated Plasterboard (2400x1200mm)

Kingspan Kooltherm K118 is one of the highest-quality insulated plasterboards available. Insulated Plasterboard is a premium performance insulation with a fibre-free rigid thermoset phenolic core.

Showing all 7 results

Kingspan Kooltherm K118 37.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £78.59.£65.49Current price is: £65.49.Kingspan Kooltherm K118 42.5mm Insulated Plasterboard (2400 x 1200mm) – 51.84m2 pallet

Original price was: £1,368.00.£1,140.00Current price is: £1,140.00.Kingspan Kooltherm K118 52.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £85.80.£71.50Current price is: £71.50.Kingspan Kooltherm K118 72.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £102.60.£85.50Current price is: £85.50.Kingspan Kooltherm K118 57.5mm Insulated Plasterboard (2400 x 1200mm) – 40.32m2 pallet

Original price was: £1,199.99.£999.99Current price is: £999.99.Kingspan Kooltherm K118 82.5mm Insulated Plasterboard (2400 x 1200mm) – 25.92m2 pallet

Original price was: £1,026.00.£855.00Current price is: £855.00.Kingspan Kooltherm K118 62.5mm Insulated Plasterboard (2400 x 1200mm) – 2.88m2

Original price was: £97.80.£81.50Current price is: £81.50.Kingspan Kooltherm K118

Kingspan Kooltherm K118 forms part of the Kooltherm K100 range. The product provides a level of unrivalled performance in the world of rigid thermoset insulation materials with a thermal conductivity of just 0.019 W/mK across all thicknesses.

When storing Kingspan K118 inside all the sheets should be stacked flat on a flat surface in a protected area and if storing outside weatherproof tarpaulin should be applied to avoid product damage. This is product is easy to install and handle and can be cut to any size.

Key features of this product include:

Insulates the concrete wall surfaces, under rafters, and interior to beam frames.

- Unaltered by air infiltration.

- Permits quick response heating.

- Water vapor resistance: Yes

- Easily installed

- Chemically inert

Thermal Performance

Kingspan Kooltherm K118 Insulated Plasterboard offers lower Lamba values that make it hold more heat when it comes to internal wall insulated plasterboard. Kooltherm K118 has been made with plasterboard bonded to the front surface and as well as a reverse facing foil, this product has been manufactured in this way with quick response heating in mind.

The reverse facing side is a low emissivity composite foil which provides better quality thermal resistance. This insulated plasterboard has a dry lining, coated by a strong adhesive bond for better protection.

Kingspan K118 is moisture resistant which can help prevent and stop condensation and mould from building up which can damage the building’s structure and effect the cavity boards performance and durability. It is also resistant to short-term contact with other liquids such as petrol, diluted acids, mineral oils and alkalis. It is recommended the boards are wiped clean before installation.

The slabs are rot proof, odourless, non-hygroscopic, do not sustain vermin, and will not encourage growth of mould, fungi or bacteria.

Safety:

Manufactured in accordance with:

- ISO 9001: 2015 (Quality Management Systems. Requirements)

- ISO 14001: 2015 (Environmental Management Systems. Requirements)

- BS OHSAS 18001: 2007 (Occupational Health & Safety Management Systems. Requirements)

- ISO 50001: 2011 (Energy Management Systems. Requirements with guidance for use).

- ISO 37301: 2021

- BES 6001 (Responsible Sourcing – Good)

More Information:

Thicknesses available: 25mm (37.5mm), 30mm (42.5mm), 40mm (52.5mm), 45mm (57.5mm), 50mm (62.5mm), 60mm (72.5mm), 70mm (82.5mm), 80mm (92.5mm)

Brand: Kingspan

Length: 2400mm

Material type: Phenolic

Thermal conductivity: 0.019 W/mK

Width: 1200mm

Fixed with drywall screws

Installation Guide For Kingspan Kooltherm K118

Before you begin:

- Ensure the wall is sound, secure, free from any contaminants and dry.

- When cutting the insulated plasterboard, it should be carried out by using a fine-toothed saw, or by scoring with a sharp knife and then snapping the board over a straight edge and then proceeding to cut the facing on the other side.

- Ensure accurate trimming to achieve close joints and continuous insulation.

Step 1:

Fix timber battens at the floor and ceiling around the room’s perimeter. Then fix further battens to the wall and around any openings or surfaces. Fix each batten approximately 75mm from its end and no more than 600mm horizontal centres.

Each batten should have a minimum depth of 25mm and width of 47mm and be backed with a strip of a damp-proof course.

Step 2:

The installation should start from an internal corner, a window or a door reveal.

Insulated plasterboard sheets should always lap the timber battens at the sheet joints. Note the timber noggins may be required where sheets of insulated plasterboard are unsupported.

Ensure each sheet is lightly butted with fixings located no less than 10mm from the bound edges of the sheet. Cut the insulated plasterboard approximately 5mm short of the floor to ceiling height.

Step 3:

Fix the sheet with either drywall screws at 300mm centres or large headed galvanized clout nails at 150mm centres. Fixing should be long enough to allow a minimum penetration into the timber batten or frame.

Drive all fixings straight, with heads embedded just below the surface of the plasterboard.

To finish seal the perimeter of the insulated plasterboard with a flexible sealant or equivalent.

Regardless of the method used, additional consideration should also be given for the fixings of cupboards and radiators etc.