Kingspan Kooltherm K108 Phenolic Cavity Board (1200x450mm)

Kingspan Kooltherm K108 Cavity Boards are designed for use as partial-filled cavity wall insulation boards. The Kooltherm K118 features a rigid phenolic core bonded to a low-emissivity composite foil, which helps to enhance the board’s thermal performance.

The board is available in a variety of thicknesses and sizes, including 450 mm by 1200 mm. Its thermal conductivity is just 0.019W/mK. Kingspan products are well-known and used by builders and architects all over the world. They provide extremely successful insulation materials due to their high-quality and incredible thermal conductivity.

Showing all 4 results

Kingspan K108 100mm Cavity Board Insulation (1200 x 450mm) – 2.7m2 pack

Original price was: £122.00.£107.33Current price is: £107.33.Kingspan K108 50mm Cavity Board Insulation (1200 x 450mm) – 5.4m2 pack

Original price was: £122.44.£108.60Current price is: £108.60.Kingspan K108 75mm Cavity Board Insulation (1200 x 450mm) – 3.24m2 pack

Original price was: £119.00.£96.99Current price is: £96.99.Kingspan K108 60mm Cavity Board Insulation (1200 x 450mm) – 4.32m2 pack

Original price was: £115.00.£103.98Current price is: £103.98.The board is available in sizes 450mm by 1200mm and thicknesses from 40mm to 150mm. Kingspan products are well-known and used by builders and architects all over the world. Due to their high-quality and incredible thermal conductivity, they provide extremely successful insulation.

Key Features:

- Meets NHBC technical requirements when used with a 50 mm cavity

- The low emissivity foil facings significantly increase the thermal resistance of the cavity

- Unaffected by air infiltration

- Easy to handle and install

- Resistant to short-term contact with petrol and with most dilute acids, alkalis, and mineral oils

- Resistant to attacks by mould and microbial growth and do not provide any food value to vermin

Kingspan Kooltherm K108 can be cut if needed with a fine-toothed saw. The insulation boards are lightweight and easy to cut, handle, and install. This product is designed to prevent thermal bridging and reduce heat loss from the property. By doing so, you will save money on monthly energy bills and provide a more comfortable and temperature-controlled environment in your commercial or residential building.

Kingspan Kooltherm K108 Cavity Board is unlikely to become ignited within the cavity. If a fire does penetrate an unventilated cavity, the amount of air present will be insufficient to support rapid combustion, and flame spread will be minimal.

A building professional should always be consulted before using insulation materials to avoid damaging your home or workplace. Wall ties should be used with Kingspan K108 to hold the ties in place. The K108 is moisture resistant, which prevents mould, rot, or condensation from developing within the property. It is also resistant to mould and microbial growth.

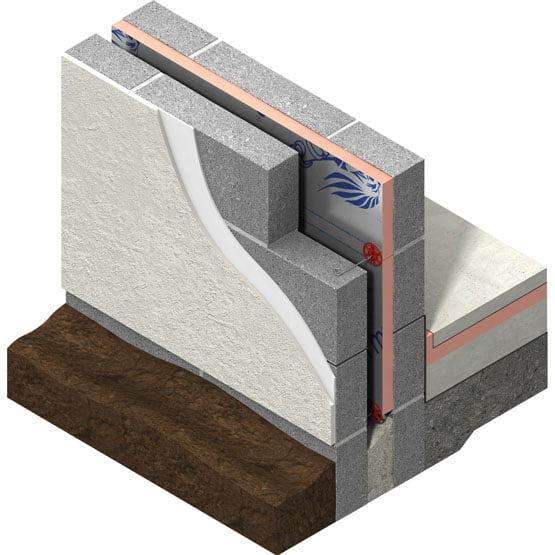

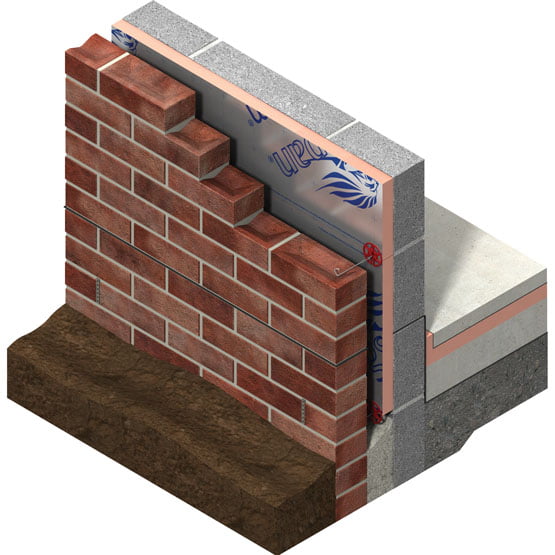

Kingspan Kooltherm K108 can be installed in a range of methods. These methods include:

- Internal Finish – Fair Faced Blockwork

- Internal Finish – 3mm Skim Coated 12.5 mm Plasterboard

- Internal Finish – Kingspan Kooltherm K118 Insulated Plasterboard

- Internal Finish – Fair Faced Blockwork

- Internal Finish – 3 mm Skim Coated 12.5 mm Plasterboard

- Internal Finish – Kingspan Kooltherm K118

Certifications:

- ISO 9001: 2015

- ISO 14001: 2015

- ISO 45001: 2018

- ISO 50001: 2018

- ISO 37301: 2021

- BES 6001 (Responsible Sourcing – Good)

How to install Kingspan K108 boards

Install wall ties in the inner leaf at 600mm horizontal centres.

or solid concrete floors, wall ties start at either one course of blockwork below the damp proof course or depending on your location a specified distance below the top surface of the ground floor perimeter insulation upstand.

For suspended timber floors wall ties start a minimum of 200mm below the top surface of the ground floor perimeter insulation upstand.

Continue constructing the inner leaf up to the next wall tie course. The next course of wall ties is position at regular horizontal centres. Extra wall ties should be positioned at the jams for all openings. The next course of blockwork should then be installed to secure the ties.

After raising each section of the inner leaf and before installing the insulation boards, extra mortar should be removed and mortar dropping cleaning from exposed edges of the installed insulation boards.

The first row of insulation boards should now be installed between the two rows of wall ties, ensure each insulation board is retained tight against the inner leaf and joins are butted. Secure each board at a minimum of three points. Addition ties may also be required to satisfy structural requirements or to ensure adequate retention of boards or cut pieces.

Build the outer leaf to the level of the top of the boards and repeat the process. If finishing at a gable, insulation board should be continued 200mm beyond the height of the top storey ceiling

And a cavity tray was installed above the insulation.

Notes:

- Cavity wall insulation is normally held in position by the wall ties used to tie the two skins of masonry together.

- All excess mortar should be removed, and mortar droppings cleaned from exposed edges of the installed insulation boards to ensure accurate insulation.

- Use of a cavity batten or cavity board is recommended to protect board edges and maintain a clear cavity.

- Ensure accurate trimming to achieve close butting joints to avoid thermal bridging with the wall.

- If correctly installed, Kingspan Kooltherm K108 can have an indefinite life. This depends on the condition of the supporting structure.

Please this is a guide ONLY and only a professional builder or architect should advise on what insulation is needed for your property and where within the structure of the building.